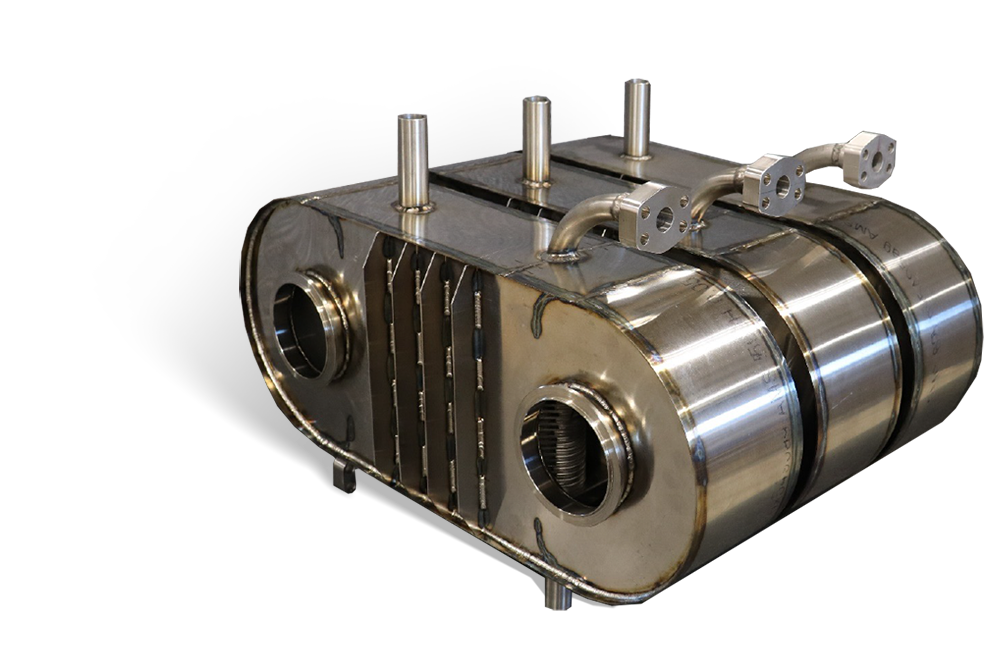

Micro channel heat exchangers have gained vital consideration in recent years as a result of their distinctive efficiency and benefits in numerous heat transfer purposes. These compact gadgets provide improved performance compared to conventional heat exchangers, making them a compelling alternative for many industries.

Efficiency

One of the key advantages of micro channel warmth exchangers is their excessive efficiency. These devices consist of quite a few small channels or tubes, usually with diameters starting from zero.5 mm to 5 mm. The small size of those channels allows for a larger floor area-to-volume ratio, leading to enhanced warmth transfer capabilities.

The increased floor space facilitates higher warmth trade between the fluid flowing inside the channels and the surrounding environment. This environment friendly heat transfer allows micro channel heat exchangers to attain larger vitality transfer charges, leading to improved general system efficiency.

Advantages

Micro channel warmth exchangers offer a number of benefits over typical heat exchangers:

Compact Size:

Due to their miniature dimensions, microchannel heat exchanger are significantly smaller and lighter than traditional counterparts. This compactness makes them ideal for applications where space is limited, such as automotive cooling systems, portable electronics, and aerospace equipment.

Reduced Refrigerant Charge:

In refrigeration and air con methods, micro channel warmth exchangers require lower refrigerant costs in comparability with typical designs. This not solely reduces environmental impression but additionally contributes to price savings by minimizing refrigerant usage.

Improved Heat Transfer Coefficients:

The intricate network of micro channels within these warmth exchangers enhances the heat switch coefficients. As a result, they’ll effectively dissipate heat even in demanding functions with high warmth loads.

Enhanced Performance:

Micro channel warmth exchangers provide higher temperature management and extra exact thermal administration. Their environment friendly design ensures uniform cooling or heating across the whole floor space, minimizing any temperature variations and making certain consistent performance.

Applications

The versatility of micro channel warmth exchangers allows their use in a variety of industries and purposes:

Automotive:

Micro channel heat exchangers discover extensive software in automotive techniques, together with engine cooling, transmission cooling, and air conditioning. Their compact measurement and improved efficiency make them a super alternative for modern vehicles, the place area optimization and power conservation are vital.

Electronics Cooling:

In the electronics business, micro channel heat exchangers play an important role in dissipating warmth generated by high-powered digital components. These heat exchangers efficiently remove excess heat, preventing overheating and guaranteeing dependable operation of devices corresponding to servers, computers, and cellphones.

Renewable Energy Systems:

Micro channel warmth exchangers are additionally utilized in renewable energy systems like photo voltaic thermal collectors and geothermal heat pumps. Their efficiency and compactness contribute to optimizing power conversion and utilization in these sustainable applied sciences.

Industrial Processes:

Various industrial processes, corresponding to chemical reactions, metal refining, and polymer manufacturing, require precise temperature management. Micro channel warmth exchangers allow efficient heat switch in these processes, guaranteeing optimal operating circumstances and enhancing productivity.

In conclusion, micro channel warmth exchangers provide outstanding efficiency and advantages in warmth transfer functions. Their compact size, lowered refrigerant cost, improved heat transfer coefficients, and enhanced performance make them a most popular choice across various industries. With ongoing advancements in supplies and manufacturing techniques, micro channel warmth exchangers are more likely to proceed revolutionizing heat exchange expertise.